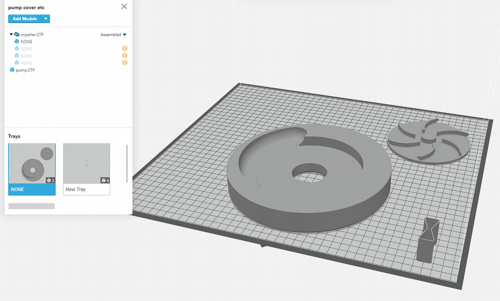

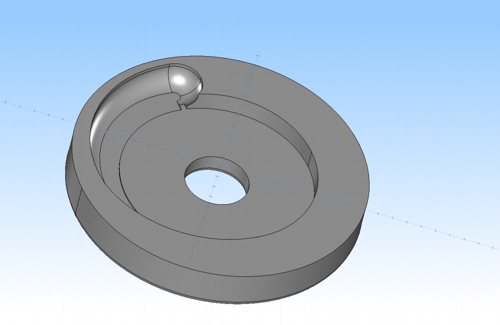

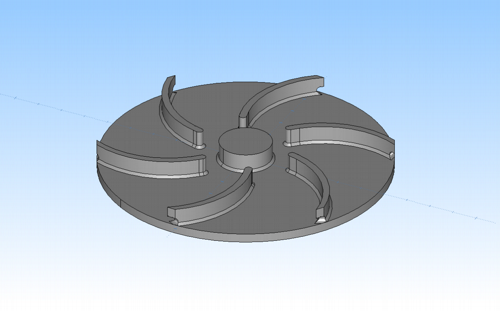

By utilising this method of manufacture, we can offer unparalleled versatility to turn CAD files into durable parts.

Be it rapid prototyping or manufacturing parts, this method of manufacture can provide significant cost and time savings compared to traditional manufacturing techniques.

3D printers create objects from plastic or other materials using the additive manufacturing process, producing objects in a succession of layers from the bottom up. The manufacturing industry is now frequently turning to 3D printing for a wide range of applications. Sectors already benefiting from the use of additive manufacturing include:

- Oil & Gas

- Aerospace

- Medical

- Automotive

- Nuclear

- Architecture

- Industrial Turbines

Our printers run a total of 13 materials adding medical grade and high temperature materials, which include zero FST material, certified for rail and aircraft interiors and approved by Airbus, making it an ideal choice for certified requirements. Materials are approved for specialised production parts in areas such as medical, aerospace, research and defence.

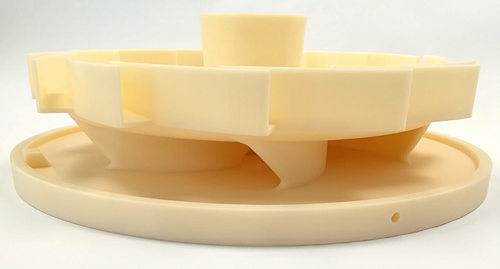

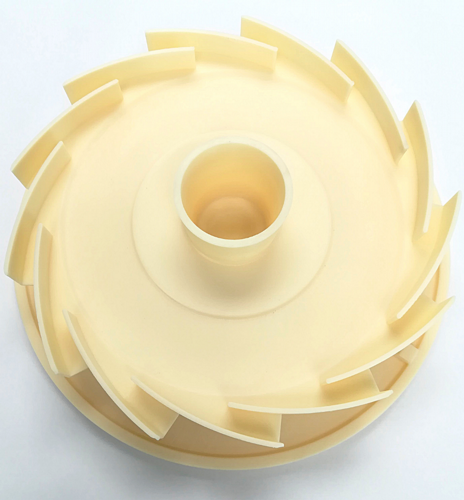

Parts manufactured this way are tough enough and flexible enough to be used as advanced conceptual models, functional prototypes, manufacturing tools and production parts.

We use high quality materials, specifically designed and selected to offer a range of properties of either strength, flexibility, heat, wear resistance, or a combination of these properties.

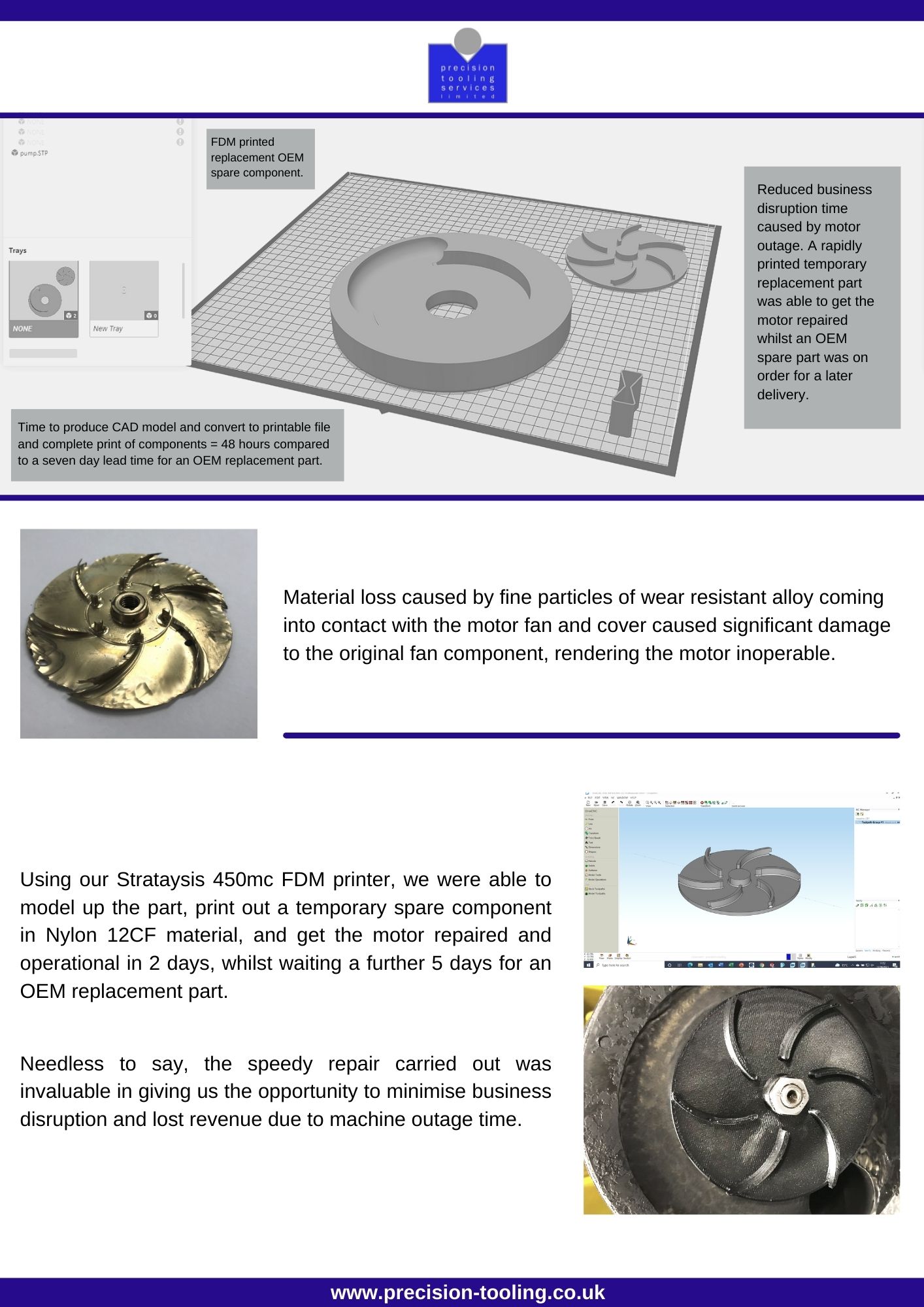

Read our latest case study below

Þ